We pride ourselves on our partnerships with renowned automotive suppliers worldwide, including Forvia Faurecia in France and Yinbaoshan in China, to develop advanced plastic components for next-generation vehicles. Our collaboration with Yinbaoshan focuses on innovative solutions for new energy vehicle (NEV) powertrain systems, ensuring durability, precision, and efficiency.

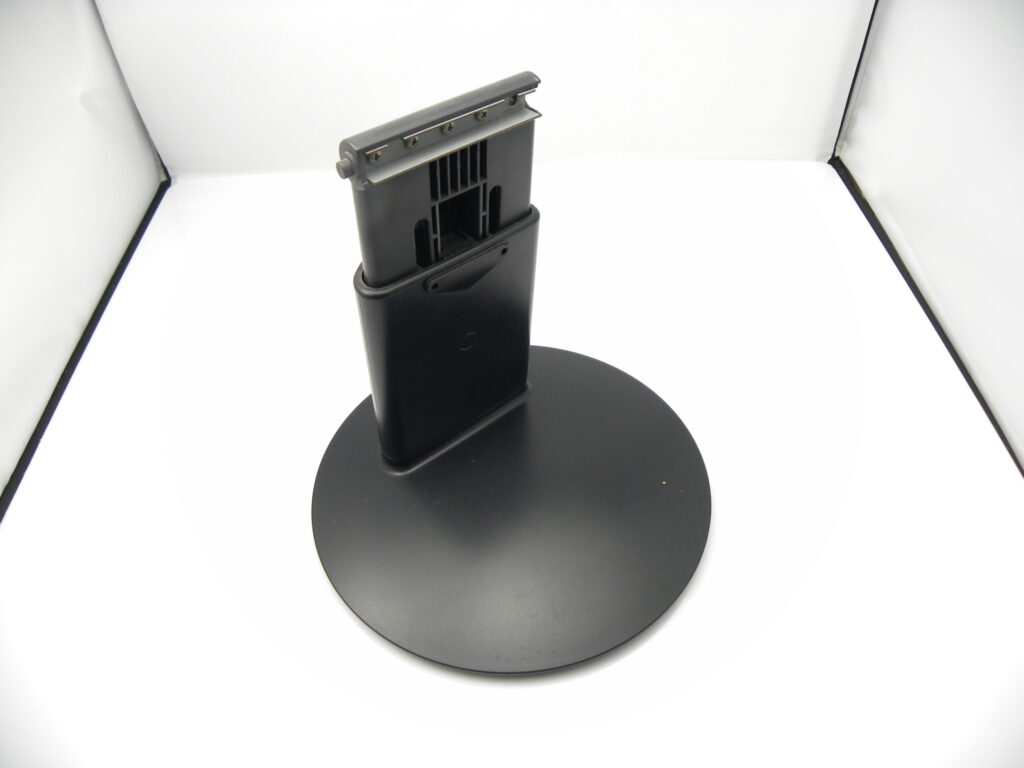

We provide end-to-end manufacturing solutions to de-risk your product lifecycle. Our services—from iterative prototyping and transition manufacturing to full-scale production and obsolescence management—are engineered to ensure supply chain resilience and operational continuity.

Our molds have enabled leading automotive brands to achieve excellence in manufacturing and design:

Luxury & Performance: Ferrari, BMW, Mercedes-Benz

Electric Innovation: Tesla, BYD, Li Auto

Global Giants: Volkswagen, Peugeot, Honda

From conceptual design to mass production, we deliver end-to-end solutions tailored to each brand’s unique requirements. Our expertise in multi-cavity molds, hot runner systems, and high-precision manufacturing ensures flawless performance for complex components.

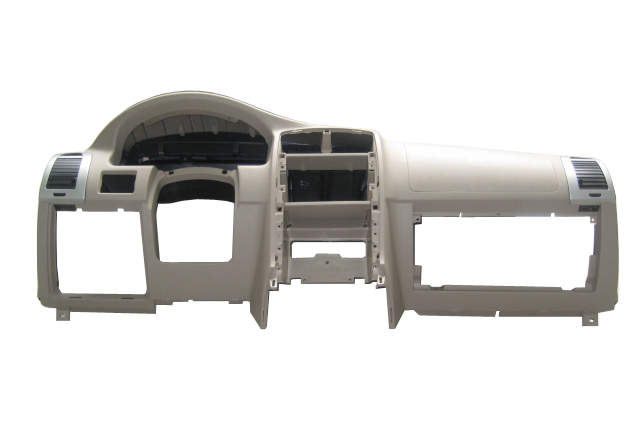

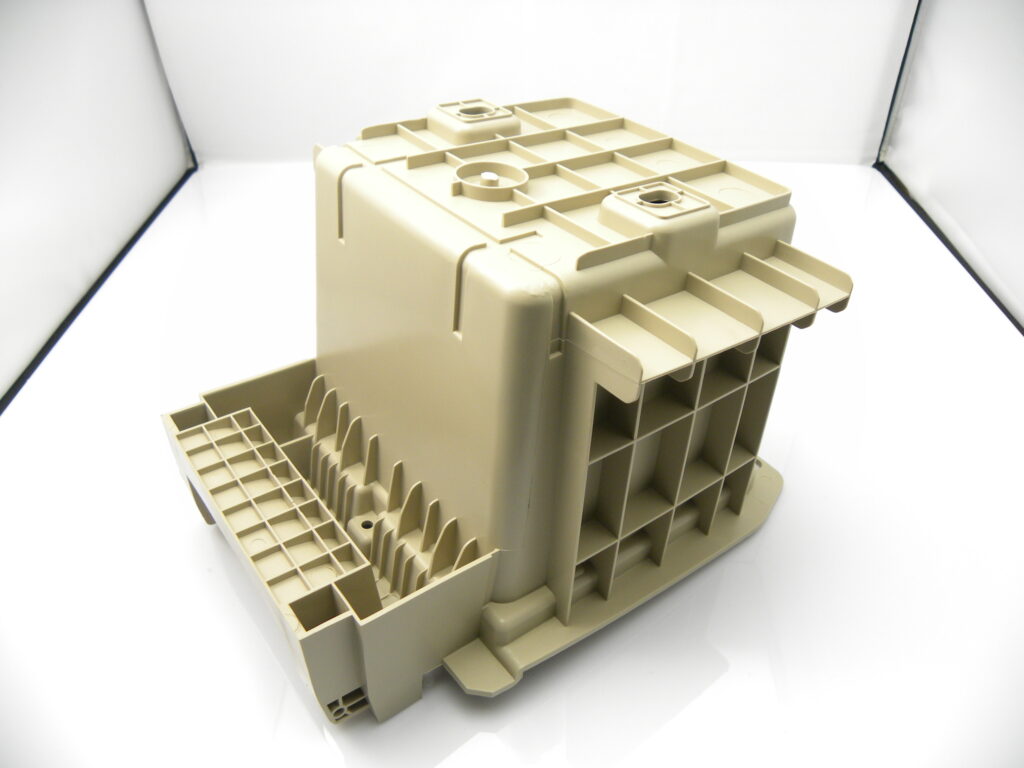

We provide precision injection molding services for the entire spectrum of automotive needs. Our capabilities include:

Interior Parts: Dashboards, vents, buttons, knobs, trim, cup holders.

Under-the-Hood Parts: Fluid reservoirs, engine covers, sensor housings, air intake components.

Exterior Parts: Front grilles, headlamp & tail light housings, wheel arch liners, bumper supports.

Lighting Systems: Housings and lenses for interior and exterior lights.

We handle complex geometries, high-gloss finishes, and high-volume production.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing.

Lorem ipsum dolor sit amet, consectetur adipiscing.

Automotive engineers select materials based on a balance of several factors:

Weight: Lighter materials improve fuel efficiency and handling.

Cost: Materials must be affordable for mass production.

Performance: This includes strength, impact resistance, heat resistance, and chemical resistance.

Aesthetics: Ability to be painted, textured, or made glossy.

Manufacturability: How easily can it be injection molded, extruded, etc.?

Detailed Breakdown by Application

Polypropylene (PP) is the king of bumpers and many exterior claddings. Its excellent chemical resistance prevents damage from road salts and fuels, it’s very lightweight, and it’s extremely cost-effective. It’s often used in a copolymer form (e.g., TPO – Thermoplastic Olefin) for better impact strength.

Polycarbonate (PC) and PC Blends (PC/ABS) are used for more demanding applications. PC/ABS combines the heat resistance and strength of PC with the flexibility of ABS. It’s commonly used for grilles, mirror housings, and wheel covers where a higher-quality finish is needed.

ABS is also used for bright trim pieces (like chrome-plated grilles) because it provides a very smooth surface for plating.

Polycarbonate (PC) is the dominant material for headlamp lenses. Its exceptional impact resistance prevents cracking from stones, and its clarity is excellent. It must be coated with a hard coat to resist UV degradation and scratching.

PMMA (Acrylic) is sometimes used for interior lenses or reflectors because it offers higher optical clarity and UV resistance than uncoated PC, but it is too brittle for external lenses.

This environment demands high heat and chemical resistance.

Nylon (Polyamide, especially PA 6/6 and PA 6) is a top choice. It maintains its strength and stiffness at high temperatures. Used for air intake manifolds, radiator end tanks, engine covers, and connectors.

Polypropylene (PP), specially formulated for heat resistance, is used for battery cases and fluid reservoirs.

Polyoxymethylene (POM / Acetal) is perfect for small precision parts like fuel system components, gears, clips, and seatbelt mechanisms due to its low friction, high stiffness, and excellent dimensional stability.

ABS and PC/ABS are widely used for interior components like the dashboard skeleton, glove boxes, and trim panels. They offer a great balance of strength, heat resistance, and a good surface finish for painting or texturing.

Polypropylene (PP) is used extensively for less structurally demanding parts like A/B/C pillar trims, glove box doors, and battery cases because it is so economical.

Acrylonitrile Styrene Acrylate (ASA) is increasingly popular for interior and exterior trim. It has similar properties to ABS but with far superior UV resistance, preventing it from fading or becoming brittle in the sun.

Thermoplastic Elastomers (TPE) / Thermoplastic Vulcanizates (TPV) have largely replaced traditional rubber for many seals and gaskets. They are easier to process (injection molding vs. vulcanization) and recyclable. Used for weather-stripping, window seals, and cowl top gaskets.

Polyurethane (PU) is used for larger, more structural flexible parts due to its toughness and abrasion resistance. Key applications include suspension bushings, foam for seats and armrests, and even body panels on some concept cars.

It has four-wheel independent drive, independent suspension, and independent steering chassis, so it has excellent mobility and obstacle surmounting capabilities. Advanced sensor configuration, including 16-line 3D lidar, ultrasonic sensor and anti-fall sensor, can achieve excellent autonomous driving and obstacle avoidance capabilities; 55-centimeter width for flexible passage through narrow and complex indoor environments.

By combining epidemic prevention and disinfection, item distribution and delivery, and exhibition display into one, operating costs are greatly reduced. The modular design of the universal mobile platform allows for easy switching of disinfection modules to other robot functional modules when disinfection functionality is not needed, thus achieving the highest level of operational efficiency。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DUOMAX twin-DEG5C.07(II)

DUOMAX-PEG5.07

4.900 kWh

15 Years

Your Vision. Our Precision.

The automotive industry demands perfection. Our advanced engineering capabilities, including 3D CAD design and CAE flow analysis, ensure that every mold is built to meet the most stringent tolerances. The result Flawless fit, perfect function, and consistent quality across high-volume production runs.

Your parts must endure extreme conditions. Our molds are crafted from premium steels and manufactured with precision machining to withstand millions of cycles without degradation. We ensure your components meet or exceed rigorous industry standards for impact resistance, thermal stability, and long-term reliability.

Time is money. Our focus on Design for Manufacturability (DFM) optimizes the molding process from the start, reducing cycle times and minimizing waste. We deliver not just superior parts, but also value that enhances your bottom line.

From initial concept and design assistance to prototyping, tooling, full-scale production, and quality assurance, we offer a seamless, integrated service. Our dedicated team works alongside yours to navigate challenges and accelerate your time-to-market.

+86-18923480246

cindyzhu@lipintooling.com

3A12, Minggao City, No.123 Yingbin Avenue, Huadu District, Guangzhou City, Guangdong Province

GLOBAL PRECISION PLASTIC MOLD MANUFACTURER