Where Micron-Level Accuracy Meets High-Volume Production. Partner with us to transform innovative concepts into market-ready, flawless products. We deliver the precision, scale, and quality that brands like Leader Brands, Including Amazon, Dell, Siemens, Sony, TCL, KONKA, Changhong, and Skyworth rely on to bring visionary consumer electronics to the global market. “Their expertise in micro-tolerances and material science was critical for the success of our latest wearable device. They are a true extension of our engineering team.”

— Director of Product Development, Leading Tech Company

1. Mastery of Scale and Precision

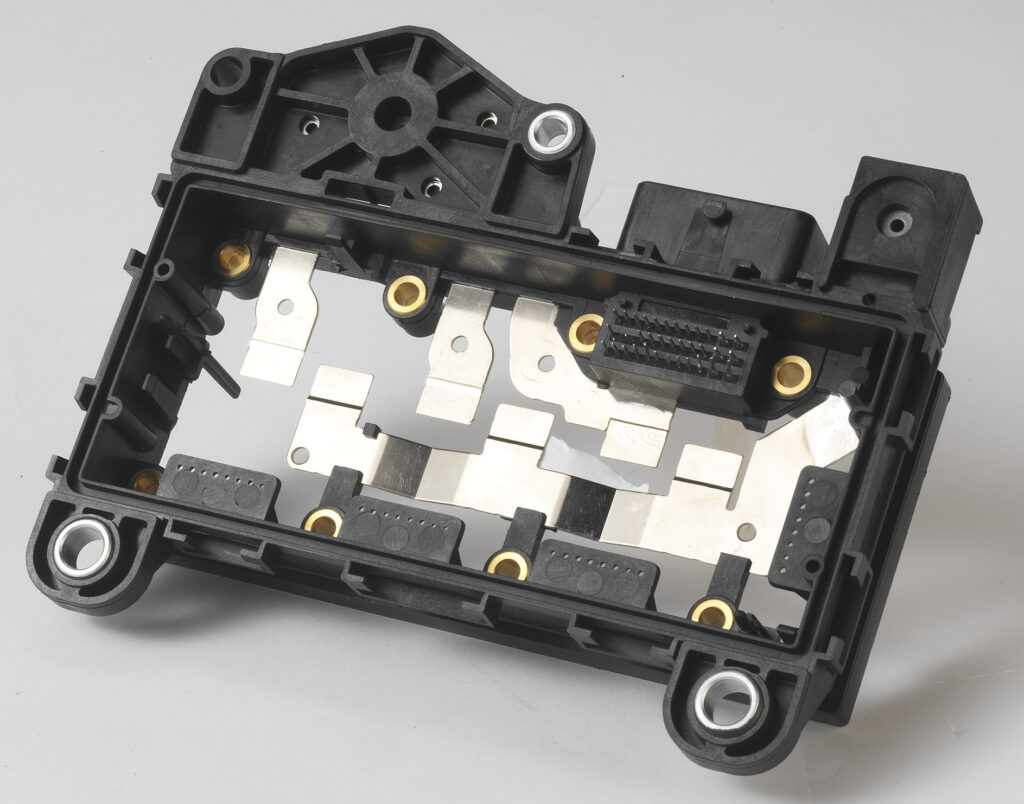

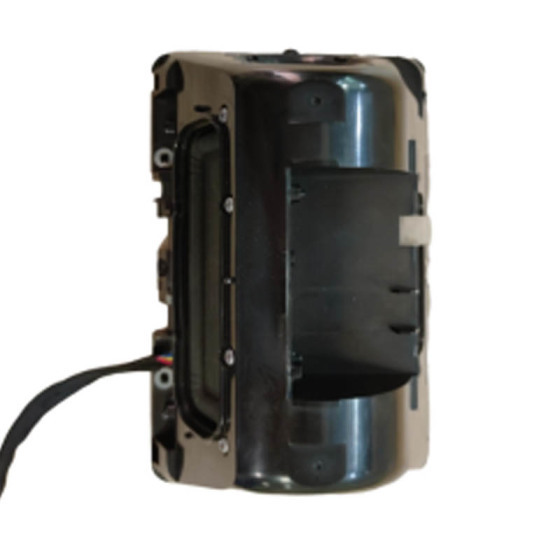

We operate a robust fleet of injection molding machines, capable of handling projects of any scale or complexity. From micro-precision components to large-scale structural housings, our capacity ensures we meet your volume and detail requirements flawlessly. Our expertise includes managing large-tonnage machines for massive components, ensuring quality and structural integrity even for challenging projects like 75-inch and 100-inch TV housings.

2. Core Technical Capabilities

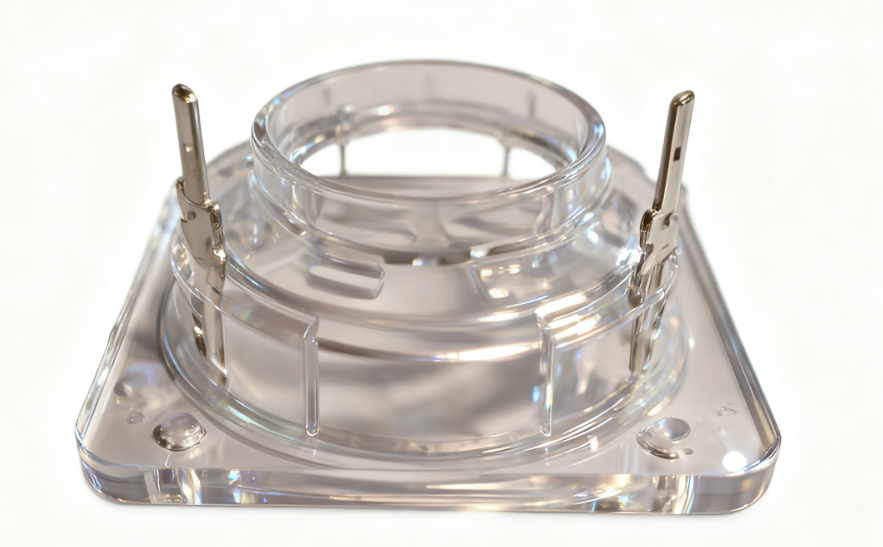

Optical-Grade Finishes: Expertise in high-gloss, matte, and textured surfaces for a premium consumer feel.

Complex Geometry & Multi-Material Molding: Successfully produce intricate parts with undercuts, snap-fits, and combined materials.

Thermal Management Solutions: Molding with advanced, thermally conductive plastics for effective heat dissipation in modern electronics.

Efficiency-Driven Innovation: We develop and implement proprietary technologies, such as customized steam controllers, to significantly enhance production efficiency and reduce costs.

3. Integrated Design & Engineering Support

Our partnership begins at the drawing board. We provide early-stage Design for Manufacturability (DFM) analysis to optimize your design for cost, performance, and assembly. We collaborate closely with client teams, offering constructive feedback to refine product structures and ensure manufacturing excellence.

4. Intelligence & Data-Driven Manufacturing

Our smart factories leverage Industrial Internet of Things (IIoT) platforms and industrial PON networks for seamless data integration. We employ sensors within molds to monitor cavity conditions in real-time, and utilize MoldFlow simulation to validate designs before cutting steel. This data-centric approach enables predictive maintenance, minimizes downtime, and guarantees consistent, high-quality output.

5. Uncompromising Quality Control

From raw material certification to final inspection, quality is embedded in our process. We implement Statistical Process Control (SPC) and conduct rigorous tests, including first-article inspection, to ensure every component meets stringent specifications and aesthetic standards.

We manufacture the critical components that power modern life:

Mobile Devices & Wearables: Smartphone housings, watch cases, fitness tracker bands, internal brackets.

Audio Products: Earbud casings, headphone sliders, speaker grilles, and acoustic chambers.

Laptops & Peripherals: Thin-and-light laptop chassis, keyboard frames, touchpad modules, and mouse enclosures.

Smart Home & IoT: Sensor housings, router casings, connector components, and camera bodies.

Portable Chargers & Power Banks: Durable, aesthetically pleasing enclosures.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing.

Lorem ipsum dolor sit amet, consectetur adipiscing.

We are your strategic manufacturing partner, specializing in high-precision plastic injection molding for the world’s leading electronics brands. We bridge the gap between ambitious design and mass production, delivering components that meet the stringent demands of aesthetics, performance, and reliability.

Our Core Capabilities:

High-Precision Mold Making: Advanced CNC machining, EDM, and CMM inspection ensure mold tools that achieve tolerances within ±0.01mm, guaranteeing part-to-part consistency.

Engineering-Grade Materials: Expertise in a wide range of polymers, including ABS, PC, PC/ABS blends, Nylon, and high-performance materials with EMI/RFI shielding, static control, and UL94 V-0 flammability ratings.

Advanced Molding Technologies:

Two-Shot Molding: For multi-material, soft-touch grips and integrated seals.

Overmolding: Combining rigid substrates with TPE/TPU for enhanced functionality and user experience.

Micro-Molding: For miniature components used in wearables, IoT devices, and micro-optics.

LSR (Liquid Silicone Rubber) Molding: For high-heat resistant, flexible seals, gaskets, and keypads.

Full In-House Secondary Operations: We provide value-added services like ultrasonic welding, precision assembly, laser etching, and cosmetic painting to deliver finished sub-assemblies.

It has four-wheel independent drive, independent suspension, and independent steering chassis, so it has excellent mobility and obstacle surmounting capabilities. Advanced sensor configuration, including 16-line 3D lidar, ultrasonic sensor and anti-fall sensor, can achieve excellent autonomous driving and obstacle avoidance capabilities; 55-centimeter width for flexible passage through narrow and complex indoor environments.

By combining epidemic prevention and disinfection, item distribution and delivery, and exhibition display into one, operating costs are greatly reduced. The modular design of the universal mobile platform allows for easy switching of disinfection modules to other robot functional modules when disinfection functionality is not needed, thus achieving the highest level of operational efficiency。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DUOMAX twin-DEG5C.07(II)

DUOMAX-PEG5.07

4.900 kWh

15 Years

Leading precision injection molder for consumer electronics. We specialize in high-volume production of micro-molding, overmolding & LSR for smartphones, wearables & IoT. DFM expertise & global scale.

+86-18923480246

cindyzhu@lipintooling.com

1th Floor, No. 4, Yigong 6th Road, Loucun Community, Xinhu Sub-district, Guangming District, Shenzhen City, Guangdong Province

GLOBAL PRECISION PLASTIC MOLD MANUFACTURER