In the world of medical device manufacturing, there is no room for error. Every component must meet the highest standards of precision, reliability, and biocompatibility. That’s where we excel. We are your strategic partner in high-volume injection molding for the medical industry. We specialize in manufacturing mission-critical components—from intricate surgical instrument parts and drug delivery systems to robust housing for diagnostic equipment.

Uncompromising Quality & Compliance: Our manufacturing processes are validated under an ISO 9001 certified quality management system. And will apply for ISO 13485 certification future. We ensure full traceability and compliance with FDA if projects request, EU MDR, and other global regulatory requirements.

Expertise in Advanced Materials: We have deep experience engineering with medical-grade polymers, including biocompatible, radiopaque, and high-temperature resistant resins, ensuring optimal performance for your application.

Cleanroom Molding Capabilities: For Class I, II, and III devices, our dedicated cleanroom environments safeguard your products from particulate contamination, guaranteeing the purity essential for patient safety.

In the demanding world of healthcare, every component must deliver uncompromising reliability. Our specialized injection molding expertise is dedicated to manufacturing high-performance, mission-critical parts that meet the stringent standards of the medical industry.

We partner with device manufacturers to produce a wide range of essential components, including:

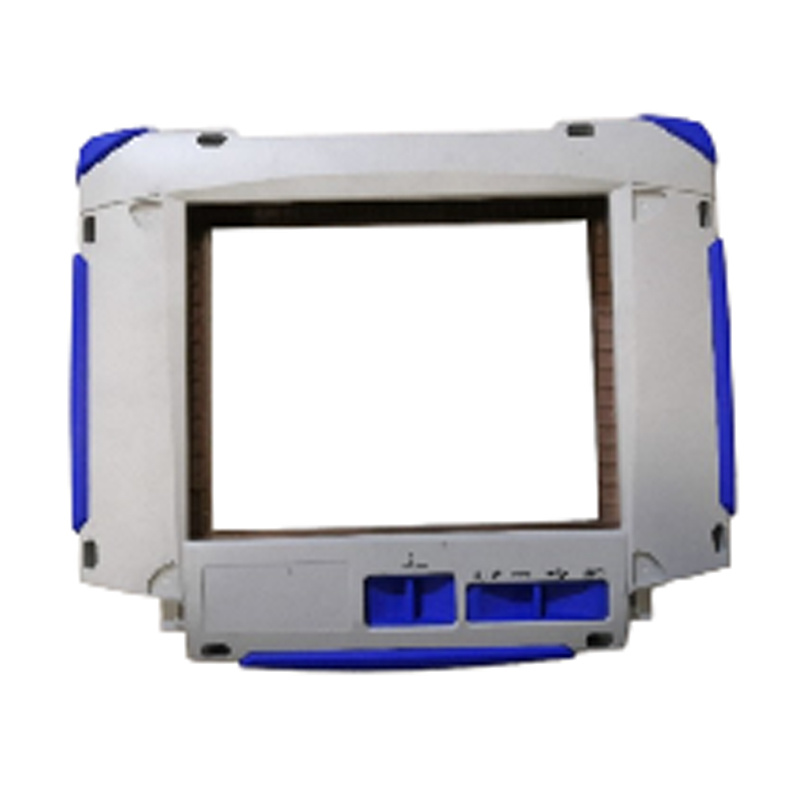

Surgical & Diagnostic Instruments: Durable housings, ergonomic handles, transparent lenses, and intricate internal gears for handheld devices, robotic surgery systems, and diagnostic equipment.

Drug Delivery Systems: Precise components for inhalers, auto-injectors, insulin pens, and IV assemblies, ensuring accurate dosing and patient safety.

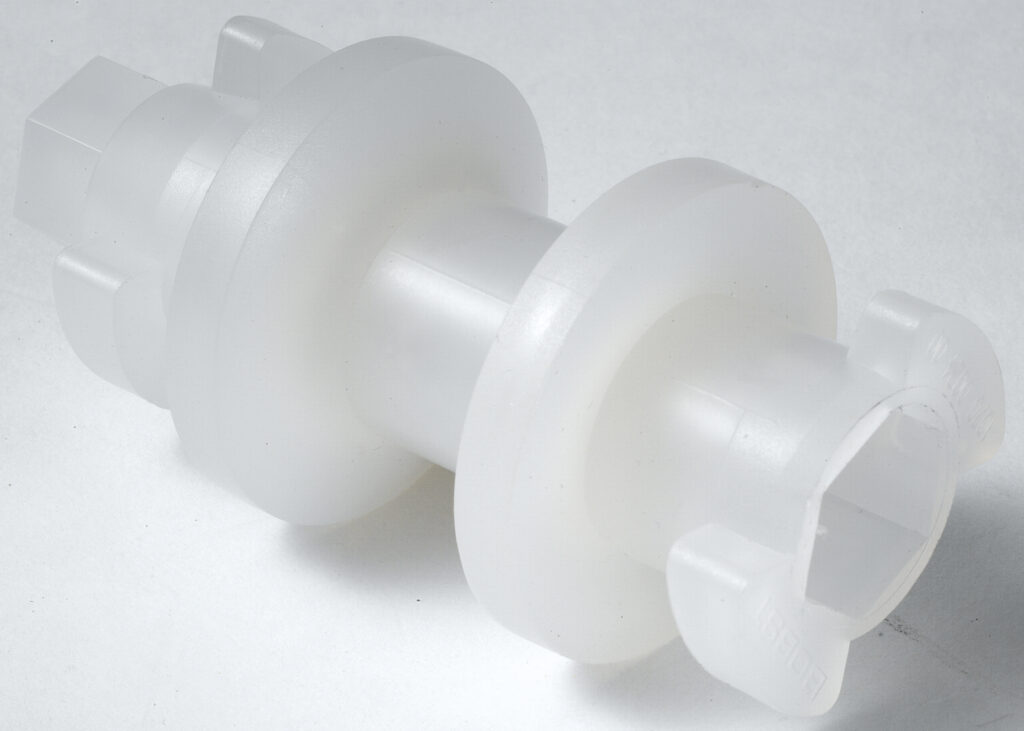

Single-Use Disposables: High-volume production of connectors, stopcocks, fluid collection chambers, and custom trays designed for sterility and cost-effectiveness.

Implantable Device Components: Manufactured with biocompatible materials under controlled environments for applications like orthopedic trials and non-active implant housings.

Labware & Consumables: Reliable pipette tips, specimen containers, and filter housings that ensure integrity and consistency in laboratory settings.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing.

Lorem ipsum dolor sit amet, consectetur adipiscing.

Choosing the right material is critical for the safety, efficacy, and longevity of medical devices. Here are some of the most trusted materials used in medical injection molding and their key applications.

1. ABS (Acrylonitrile Butadiene Styrene)

A versatile and economical thermoplastic prized for its excellent impact resistance, rigidity, and ease of processing. It is ideally suited for non-implantable medical equipment housings, enclosures, and durable components that require structural integrity.

2. Polycarbonate (PC)

Renowned for its exceptional clarity, high impact strength, and ability to withstand repeated sterilization cycles (including autoclaving). These properties make PC a top choice for transparent medical components, such as surgical instrument lenses, flow meters, and housings for critical care devices.

3. Polyethylene (PE)

This lightweight and chemically resistant polymer is available in various densities. Its inertness makes it suitable for single-use medical packaging, bottles, containers, and disposable products where sterility and cost-effectiveness are paramount.

4. Polyurethane (PU)

Offers an outstanding balance of flexibility, toughness, abrasion resistance, and biocompatibility. PU is extensively used in critical applications like medical tubing, catheters, wound care products, and certain short-term implantable devices.

5. Silicone

A premium elastomer known for its superior biocompatibility, extreme temperature stability, and inherent flexibility. Silicone is the material of choice for high-performance medical tubing, seals, gaskets, soft-touch components, and long-term implants.

6. NBR (Nitrile Rubber)

Provides excellent resistance to oils, fuels, and many chemicals. Its primary medical applications include examination and surgical gloves, as well as specific seals and diaphragms that may encounter oils or hydrocarbons.

7. EPDM (Ethylene Propylene Diene Monomer)

Excels in resisting heat, ozone, weathering, and steam sterilization. EPDM is commonly specified for autoclavable seals, gaskets, and valve components that must maintain resilience through numerous sterilization cycles.

8. Fluoroelastomers (FKM/Viton®)

Representing the highest standard in chemical and heat resistance, FKM elastomers are essential for components exposed to aggressive chemicals, fuels, or high-temperature fluids, ensuring reliability in the most demanding medical environments.

It has four-wheel independent drive, independent suspension, and independent steering chassis, so it has excellent mobility and obstacle surmounting capabilities. Advanced sensor configuration, including 16-line 3D lidar, ultrasonic sensor and anti-fall sensor, can achieve excellent autonomous driving and obstacle avoidance capabilities; 55-centimeter width for flexible passage through narrow and complex indoor environments.

By combining epidemic prevention and disinfection, item distribution and delivery, and exhibition display into one, operating costs are greatly reduced. The modular design of the universal mobile platform allows for easy switching of disinfection modules to other robot functional modules when disinfection functionality is not needed, thus achieving the highest level of operational efficiency。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DUOMAX twin-DEG5C.07(II)

DUOMAX-PEG5.07

4.900 kWh

15 Years

We offer a comprehensive suite of services under one roof. By integrating traditional precision CNC machining with advanced digital solutions like 3D printing, we provide the perfect technology for each application, streamlining your supply chain and accelerating time-to-market.

Our greatest asset is our team. With over ten years of specialized experience in automotive manufacturing, our skilled engineers are more than producers; they are partners who proactively optimize designs for manufacturability, performance, and cost-effectiveness

+86-18923480246

cindyzhu@lipintooling.com

1th Floor, No. 4, Yigong 6th Road, Loucun Community, Xinhu Sub-district, Guangming District, Shenzhen City, Guangdong Province

GLOBAL PRECISION PLASTIC MOLD MANUFACTURER