Livepoint is a premier injection molding specialist, engineered to meet the rigorous demands of the new energy industry. We are more than just a manufacturer; we are a strategic partner in progress, providing the critical plastic and composite parts that power the next generation of technology.

We understand the unique challenges of your industry. Our expertise is focused on delivering high-quality molded solutions for:

Electric Vehicles (EVs):

Battery Systems: Housings, cell holders, busbar insulators, connectors, and thermal management components with UL94 V-0 flame retardancy.

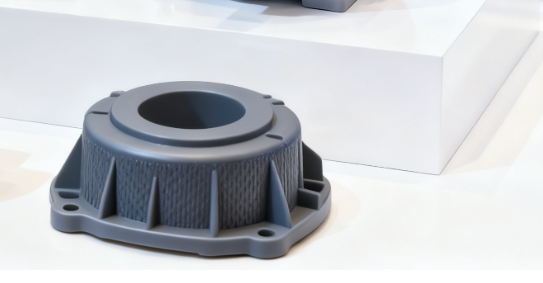

Powertrain & E-Motor: Sensor housings, end caps, insulation parts, and connectors resistant to high temperatures and electromagnetic interference.

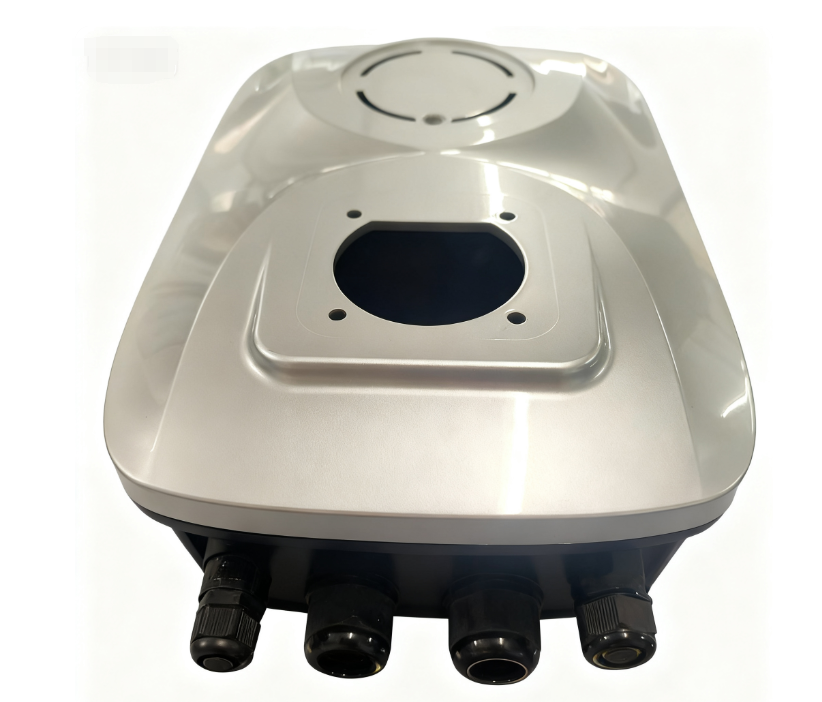

Charging Infrastructure: Charging gun housings, socket assemblies, cable management, and robust internal components.

Interior & Exterior: Lightweight, durable parts that contribute to vehicle efficiency and aesthetics.

Energy Storage Systems (ESS):

Battery module enclosures, thermal management components, and robust structural parts designed for safety and longevity in demanding environments.

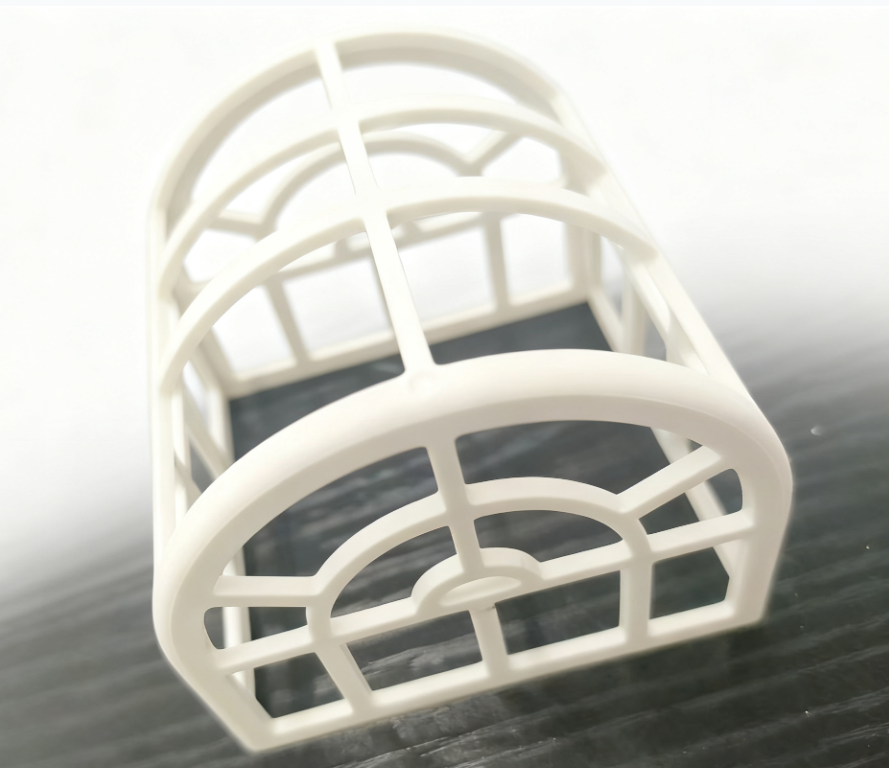

Hydrogen Fuel Cells:

Complex components for bipolar plates, sensor housings, and fluid management systems that require exceptional chemical resistance and dimensional stability.

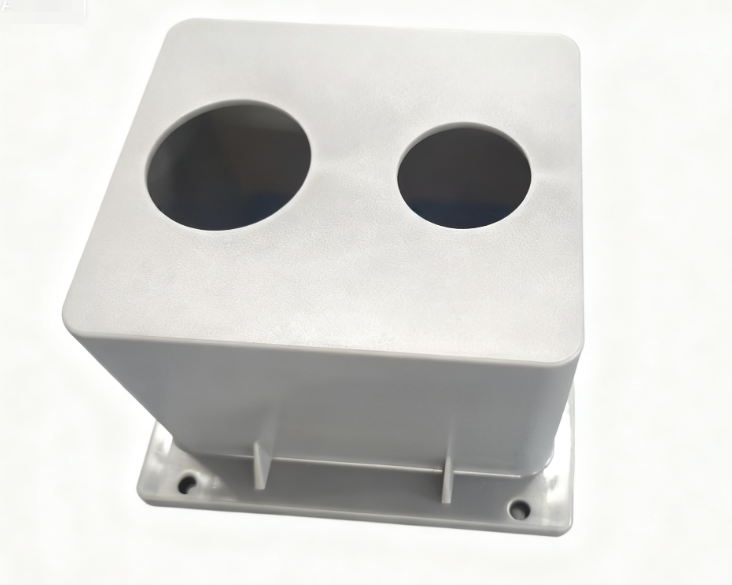

Solar & Wind Power:

Junction boxes, connector housings, sensor protectors, and durable internal gears that withstand harsh outdoor conditions and UV exposure.

Electric Vehicle Battery Systems

Secure • Protected • Efficient

Explore our high-precision battery modules, cell holders, and flame-retardant enclosures – engineered for optimal thermal management and maximum safety under the most demanding conditions.

Next-Generation Charging Solutions

Durable • Reliable • Connected

From ergonomic charging gun housings to complex socket assemblies, witness the seamless integration of user-centric design and robust performance.

Advanced Powertrain Components

High-Temp Resistant • EMI Shielded

Discover sensor housings and motor insulation parts that withstand extreme temperatures while ensuring flawless electromagnetic compatibility.

Energy Storage Innovations

Intelligent • Safe • Scalable

See how our battery enclosure systems and thermal management components are setting new standards for energy storage solutions worldwide.

Hydrogen Fuel Cell Technology

Chemically Resistant • Dimensionally Stable

Experience our breakthrough components for bipolar plates and fluid management systems – where chemical resistance meets perfect dimensional stability.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing.

Lorem ipsum dolor sit amet, consectetur adipiscing.

The transition to new energy solutions demands components that operate at the limits of performance and safety. Failure is not an option. At Livepoint, we understand that success is defined not just by what we make, but by the potential problems we eliminate throughout the molding process.

We proactively engineer-out risks to ensure the integrity, safety, and longevity of your most critical components.

The Risk: Short circuits, current leakage, dielectric breakdown, and material degradation under high thermal loads.

Our Proactive Mitigation:

Material Science Expertise: We meticulously select and test high-performance polymers with certified CTI (Comparative Tracking Index), high HDT (Heat Deflection Temperature), and UL94 V-0 flame retardancy to meet stringent automotive (e.g., USCAR) and electrical standards.

Precision Mold Flow Analysis: We simulate the filling and packing phases to prevent weld lines in critical insulating areas and ensure uniform fiber orientation in conductive compounds, guaranteeing consistent electrical properties.

Controlled Cleanliness: We implement controlled environments and handling protocols for sensitive components like battery connectors to prevent particulate contamination that could lead to electrical failure.

The Risk: Part deformation, creep, cracking, or failure due to mechanical stress, pressure, or long-term environmental exposure.

Our Proactive Mitigation:

Robust DFM (Design for Manufacturability): Our engineers collaborate with you from the outset to optimize wall thickness, add strategic ribs, and eliminate sharp corners to mitigate stress concentration.

Advanced Gate & Cooling Design: We optimize gate locations and cooling channel geometry to control shrinkage and warpage, ensuring parts meet critical dimensional tolerances for perfect assembly and function.

Long-Term Performance Testing: We go beyond initial specs, performing accelerated aging and environmental stress tests to predict and design for long-term performance.

The Risk: Swelling, embrittlement, or corrosion caused by exposure to coolants, battery electrolytes, chemicals, or UV radiation.

Our Proactive Mitigation:

Application-Specific Material Validation: We have extensive experience testing material compatibility with a wide range of chemicals used in new energy applications, ensuring we specify resins with proven chemical resistance (e.g., PPS, PPA for harsh environments).

Protective Finishes & Coatings: Where necessary, we integrate capabilities for secondary processes like plating or applying protective coatings to enhance UV and chemical resistance for exterior components.

The Risk: Leaks in battery housings, fluid management systems, or outdoor enclosures, leading to system failure and safety hazards.

Our Proactive Mitigation:

Integrated Sealing Solution Design: We design parts with integrated sealing grooves and gasket interfaces, ensuring compression limits are met without stress relaxation over time.

Process Stability for Consistency: We utilize scientific molding principles to maintain ultra-stable process windows. This eliminates variations in part density and dimensions that are the primary cause of sealing failures in high-volume production.

The Risk: Inconsistent part quality, color variations, and dimensional drift over millions of cycles, leading to line stoppages and recalls.

Our Proactive Mitigation:

Full Automation & Robotics: Our automated production cells with in-line vision inspection and automated sprue pickers ensure consistent cycle times and eliminate human error, part-after-part.

Real-Time SPC (Statistical Process Control): We monitor critical process parameters in real-time, allowing for immediate intervention long before a part falls out of specification.

Comprehensive Tooling Maintenance: Our proactive mold maintenance and cleaning schedules prevent unforeseen downtime and ensure tooling longevity, protecting your supply chain.

It has four-wheel independent drive, independent suspension, and independent steering chassis, so it has excellent mobility and obstacle surmounting capabilities. Advanced sensor configuration, including 16-line 3D lidar, ultrasonic sensor and anti-fall sensor, can achieve excellent autonomous driving and obstacle avoidance capabilities; 55-centimeter width for flexible passage through narrow and complex indoor environments.

By combining epidemic prevention and disinfection, item distribution and delivery, and exhibition display into one, operating costs are greatly reduced. The modular design of the universal mobile platform allows for easy switching of disinfection modules to other robot functional modules when disinfection functionality is not needed, thus achieving the highest level of operational efficiency。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DUOMAX twin-DEG5C.07(II)

DUOMAX-PEG5.07

4.900 kWh

15 Years

Engineering Certainty. Powering Progress.

High-Temperature Plastics (PPS, PPA, PEI)

Flame-Retardant Plastics (V-0 Rated Nylons, PC)

Long-Fiber Reinforced Thermoplastics (LFT)

Electrically Conductive & Shielding Compounds

+86-18923480246

cindyzhu@lipintooling.com

1th Floor, No. 4, Yigong 6th Road, Loucun Community, Xinhu Sub-district, Guangming District, Shenzhen City, Guangdong Province

GLOBAL PRECISION PLASTIC MOLD MANUFACTURER