Your trusted partner for high-volume, high-precision injection molding. From concept to mass production, we deliver exceptional quality for the plumbing, toy, household, and industrial sectors.

We specialize in the design, prototyping, and mass production of plastic injection molds and components. Our state-of-the-art facilities and rigorous quality control ensure that every part we produce meets the highest standards of precision, durability, and value.

High-Volume Production

Precision Mold Design & Manufacturing

Full-Color & Multi-Material Molding

Stringent Quality Assurance

Supply Chain & Logistics Management

In the world of plumbing and fluid transfer, failure is not an option. We manufacture robust, precision-engineered components that withstand pressure, temperature, and corrosive substances.

We Produce:

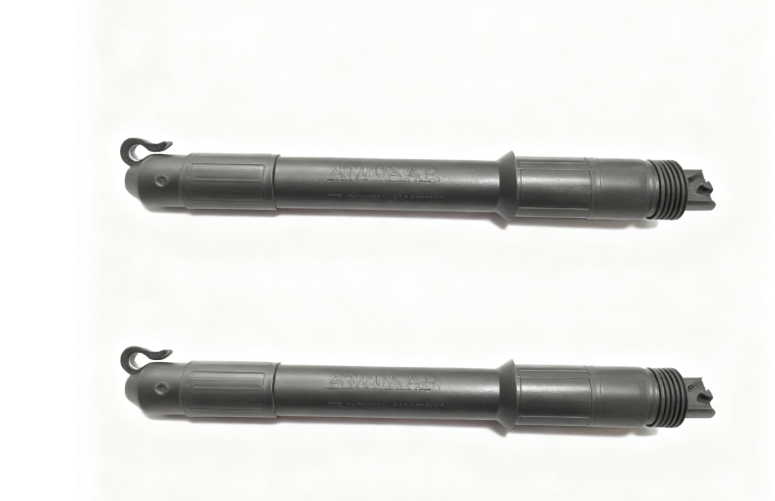

Pipe Fittings (Elbows, Tees, Couplings)

Valves & Faucet Components

Pump Housings & Impellers

Connectors & Seals

Custom Plumbing Solutions

Our Value Proposition:

Material Expertise: Selection of engineering-grade polymers (PP, POM, Nylon) for chemical and pressure resistance.

Perfect Sealing: Precision molding ensures leak-proof performance from the first part to the millionth.

Durability Certified: Components tested for long-term performance under stress and UV exposure.

The toy industry demands creativity, safety, and vibrant aesthetics. We produce fun, reliable, and child-safe components that bring your most imaginative designs to market.

We Produce:

Action Figure & Doll Parts

Building Block Components

Wheels, Gears, & Moving Parts

Electronic Toy Housings

Outdoor Play Equipment Parts

Our Value Proposition:

Uncompromising Safety: Full compliance with international toy safety standards (ASTM F963, EN-71).

Vibrant Aesthetics: Expertise in color matching, surface finishes (textured, glossy), and de-molding of intricate details.

Durability for Play: Parts designed to withstand impact and repeated use without failure.

From the kitchen to the bathroom, consumers expect products that are functional, ergonomic, and visually appealing. We help you create household items that excel in form and function.

We Produce:

Kitchenware & Appliance Housings

Storage Container Lids & Bases

Personal Care Product Housings (e.g., electric toothbrushes, razors)

Cosmetic Cases & Components

Furniture Parts & Hardware

Our Value Proposition:

Ergonomic Design Support: We optimize parts for user comfort and intuitive handling.

Aesthetic Excellence: Superior surface finish quality for a premium look and feel.

Cost-Effective Production: Efficient mold design and high-volume manufacturing to maximize your profitability.

When downtime is costly, your components cannot fail. We manufacture high-tolerance, robust parts for a wide range of industrial applications, from automation to automotive.

We Produce:

Enclosures & Housings

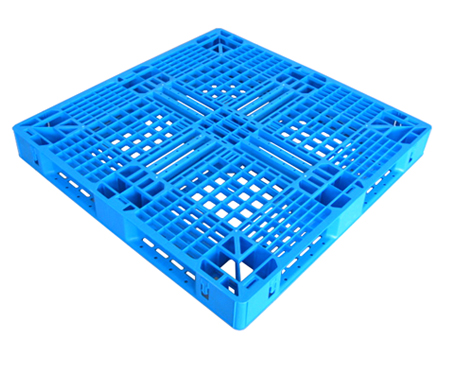

Gears, Rollers, & Guides

Connectors & Assemblies

Custom Machine Components

Material Handling Parts

Our Value Proposition:

High-Tolerance Molding: Capable of holding tight tolerances for critical-fit applications.

Engineering-Grade Materials: Expertise with filled polymers, high-temperature resins, and other specialty materials.

Consistency & Traceability: Rigorous quality documentation and lot traceability for every production run.

In the rapidly evolving LED industry, performance and longevity start at the component level. We deliver high-precision injection molded parts that meet the critical demands of thermal management, optical clarity, and durability. Partner with us to bring efficiency and reliability to your LED applications.

We Produce:

LED Lenses & Optical Components

Our Value: Engineering Light for Peak Performance

We master the science of light and heat. Our precision molds and processes produce optical components with flawless finishes and consistent accuracy, ensuring perfect light distribution. Simultaneously, we specialize in advanced materials like Thermally Conductive Plastics to effectively manage heat, safeguarding LED longevity and enhancing overall system reliability.

What We Do: Our Core Capabilities

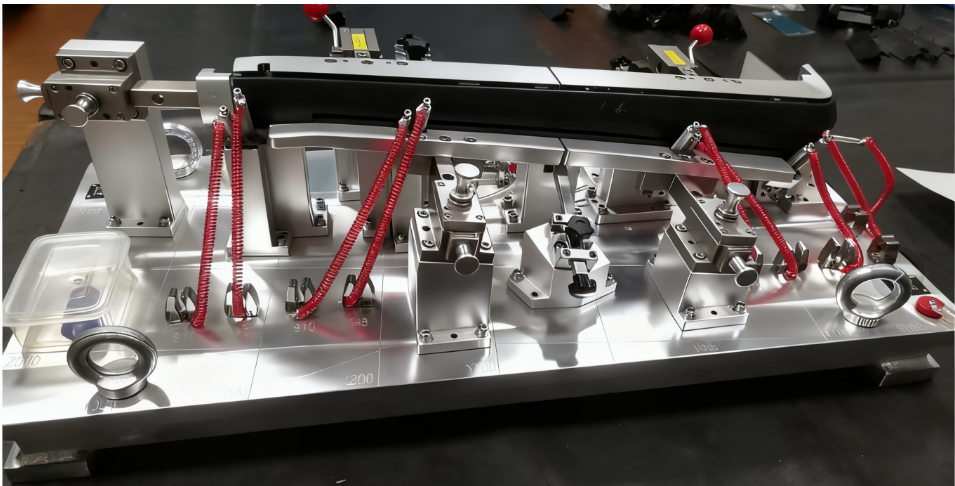

High-Precision Mold Design & Manufacturing: We engineer and produce complex, high-cavitation molds with ultra-tight tolerances, specifically for intricate UHV components like insulators, bushings, and sensor housings.

Advanced Material Expertise: We process high-performance engineering plastics and composites, including:

High-Temperature Plastics: PEEK, PEI (Ultem), PPS, PSU.

High-Track & Flame-Retardant Materials: Specialized nylons, polycarbonates, and thermosets that meet stringent UL and IEC standards.

Cleanroom & Controlled Environment Molding: We operate dedicated cleanroom injection molding facilities to prevent contamination, ensuring the dielectric integrity and surface quality of every part.

Full-Process Validation & Quality Assurance: From DFM (Design for Manufacturability) and flow analysis to rigorous CTQ (Critical-to-Quality) checks, we embed quality at every stage. Our capabilities include CMM, CT scanning, and dielectric strength testing.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing.

Lorem ipsum dolor sit amet, consectetur adipiscing.

We are a team of passionate engineers and manufacturing experts dedicated to your success. Our commitment goes beyond making parts; we build lasting partnerships.

Proven Expertise: Decades of combined experience across all our target industries.

Quality as Standard: Our ISO 9001& IATF 16949 certified quality management system is the backbone of our operations.

Global Reach, Local Service: We serve clients worldwide with a responsive, personalized approach.

Driven by Innovation: We continuously invest in new technologies and processes to give you a competitive edge.

It has four-wheel independent drive, independent suspension, and independent steering chassis, so it has excellent mobility and obstacle surmounting capabilities. Advanced sensor configuration, including 16-line 3D lidar, ultrasonic sensor and anti-fall sensor, can achieve excellent autonomous driving and obstacle avoidance capabilities; 55-centimeter width for flexible passage through narrow and complex indoor environments.

By combining epidemic prevention and disinfection, item distribution and delivery, and exhibition display into one, operating costs are greatly reduced. The modular design of the universal mobile platform allows for easy switching of disinfection modules to other robot functional modules when disinfection functionality is not needed, thus achieving the highest level of operational efficiency。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DUOMAX twin-DEG5C.07(II)

DUOMAX-PEG5.07

4.900 kWh

15 Years

+86-18923480246

cindyzhu@lipintooling.com

1th Floor, No. 4, Yigong 6th Road, Loucun Community, Xinhu Sub-district, Guangming District, Shenzhen City, Guangdong Province

GLOBAL PRECISION PLASTIC MOLD MANUFACTURER