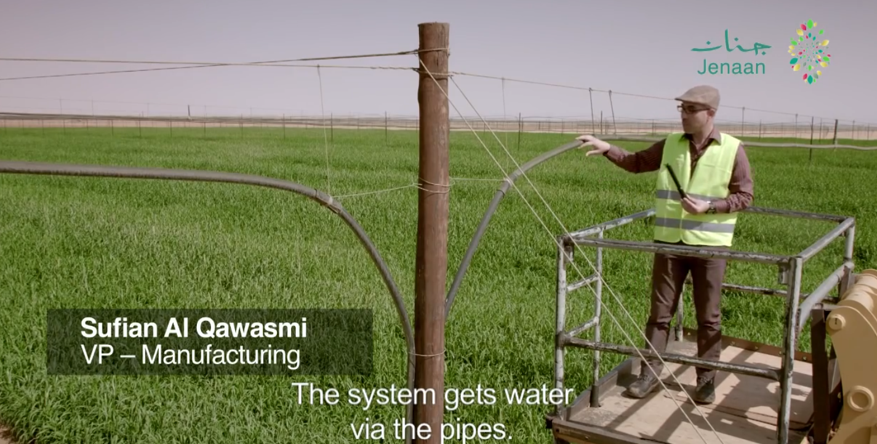

Our company was engaged to design, engineer, and manufacture the core components for the innovative “Rainfall Sprinkler.” This project required precision mold injection expertise to create a system that replicates the gentle, nurturing properties of natural rainfall. The result is an irrigation solution that enhances crop yield and quality through superior water delivery, combining biome inspiration with advanced manufacturing.

The Core Innovation: Mimicking Rain

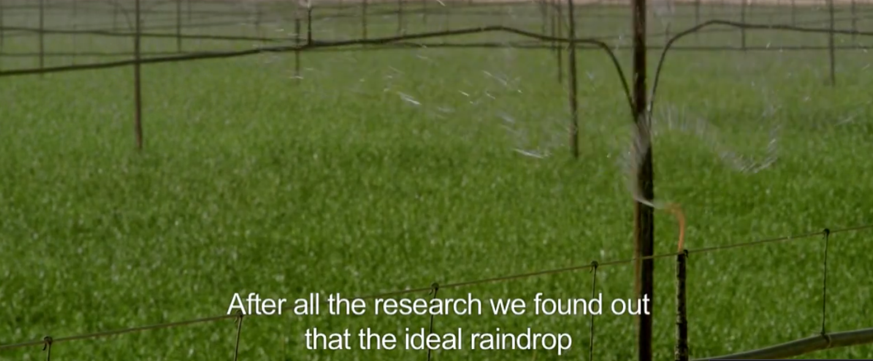

Unlike conventional sprinklers, this system is engineered to simulate the soft impact and optimal droplet size of natural rain. This prevents soil erosion and plant damage, encouraging deeper root growth and healthier crops.

Ideal Raindrop Measurement:

Through extensive research, the ideal droplet diameter for effective and gentle irrigation was identified as 3mm. Our manufacturing process was critical in achieving this consistency at scale.

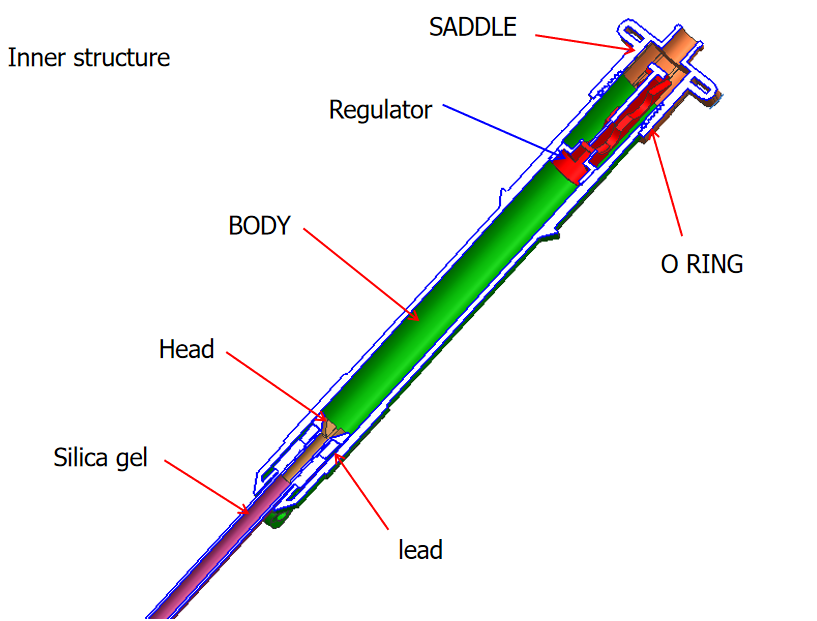

The central housing units. These require high-strength, UV-resistant plastics to withstand outdoor pressure and environmental stress.

A precision part ensuring consistent water pressure and flow rate, critical for maintaining the 3mm droplet size.

Provides structural stability and secure mounting. Molded for durability and precise fit.

Critical for creating a leak-proof system. We utilize specialized liquid injection molding (LIM) for the high-grade Silica Gel seals, ensuring long-term flexibility and water-tight integrity.

The complex network through which water flows. This involves extruding and molding with a special, flexible silicone material that resists kinking and mineral buildup.

Water Intake: Compressed water enters the system at the base.

Pressure Regulation: Our molded Regulator component normalizes the pressure.

Channeling: Water is guided through our specially molded internal channels.

Droplet Formation: Water is forced through the fine, silicone Soft Tube, creating the ideal 3mm droplets that mimic natural rainfall.

This seamless operation is only possible due to the dimensional accuracy and reliability of every injection-molded part.

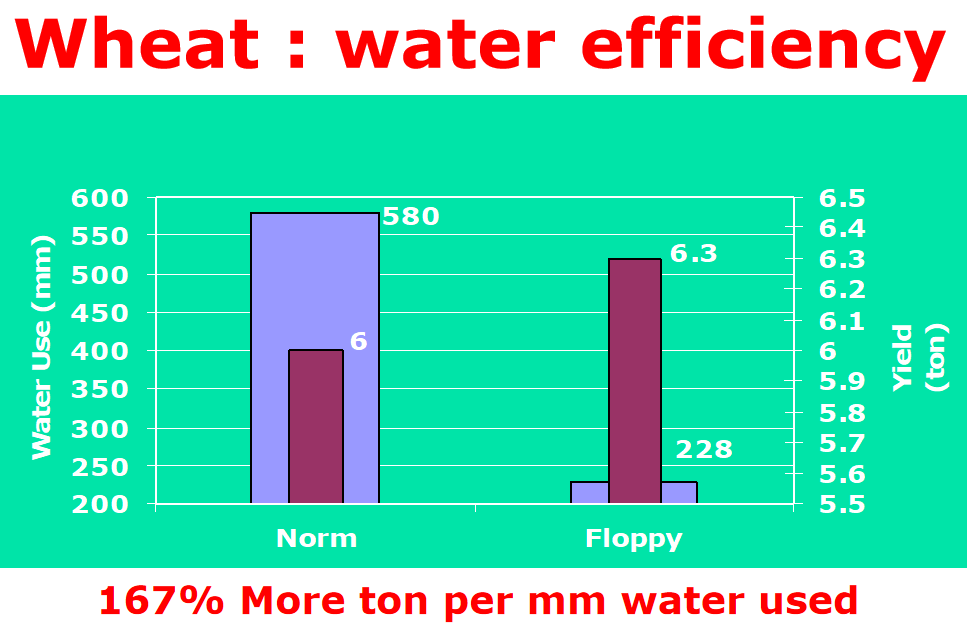

The precision of our manufactured components directly translates to the system’s field performance:

High Yields & Good Product Quality: Consistent, gentle watering reduces plant stress and promotes uniform growth.

High Efficiency: Targeted droplet size minimizes water waste from evaporation and runoff.

Flexible System for Open Fields: The durability and reliability of the plastic and silicone components allow for deployment across vast and varied terrains.

Easy Management: The robust design and reliable seals mean reduced maintenance and easier operation for end-users.

Our core advantage is the proprietary integration of specialized molding equipment, innovative mold design, and standardized processes—the only solution enabling mass production of next-generation hybrid insulators globally.

We expertly handle engineering-grade plastics for structural parts and specialized silicones for flexible, sealed components.

From the O-Ring groove to the complex internal water channels, we ensure every part meets strict tolerances for perfect assembly and function.

We provided comprehensive services from design-for-manufacturability (DFM) advice and rapid prototyping to full-scale production

If you are developing a product that requires precision, reliability, and innovative material solutions, we have the mold injection expertise to make it a market success

Provides structural stability and secure mounting. Molded for durability and precise fit.

Provides structural stability and secure mounting. Molded for durability and precise fit.

Critical for creating a leak-proof system. We utilize specialized liquid injection molding (LIM) for the high-grade Silica Gel seals, ensuring long-term flexibility and water-tight integrity.

GLOBAL PRECISION PLASTIC MOLD MANUFACTURER