Mold Design & Engineering

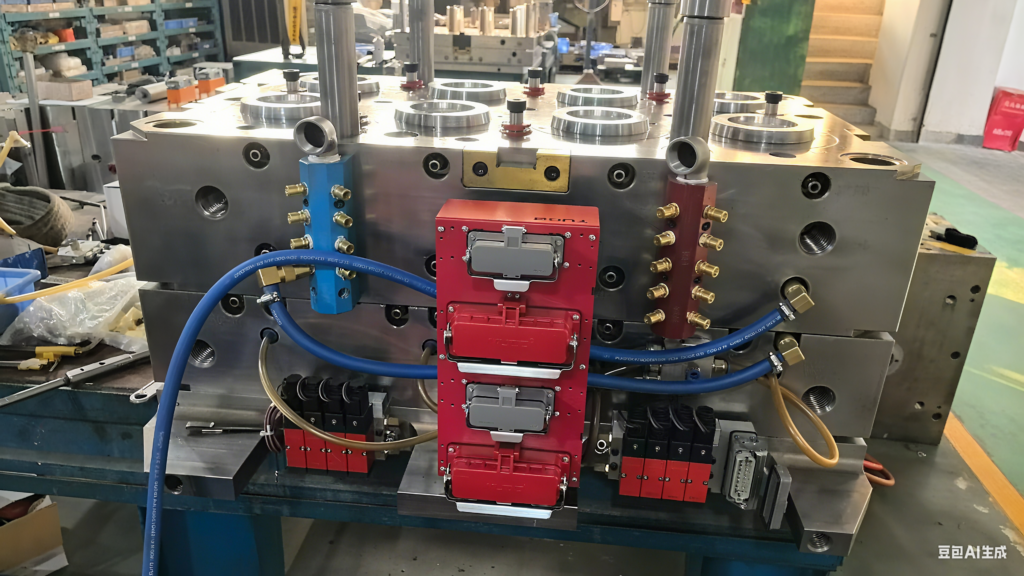

Precision Mold Making

High-Volume Injection Molding

Post-Molding & Assembly

Rigorous Quality Control

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam quis.

Lorem ipsum dolor sit amet consectetur.

Lorem ipsum dolor sit amet consectetur.

Lorem ipsum dolor sit amet consectetur.

Accelerate your product launch with our rapid tooling services. We produce high-quality, cost-effective molds in significantly less time than traditional tooling, enabling faster iteration and low to mid-volume manufacturing of functional prototypes and production parts. Whether for testing, market validation, or short-run production, we help you stay agile and competitive.

Livepoint delivers end-to-end injection molding solutions. From material selection and precision toolmaking to fabrication, finishing, and rigorous inspection, our global team handles projects of any scale or complexity. We provide three tailored service tiers, ensuring you get the optimal balance of volume, speed, and cost for your project.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus luctus.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus luctus.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus luctus.

Rapid prototyping is the process of creating a physical representation of a new product design. It serves as an initial validation step before full-scale production, playing a crucial role in evaluating the appearance, tactile quality, and functionality of the final product. Product development teams rely on prototypes for various purposes—including functional testing, design approval, iterative improvements, crowdfunding demonstrations, trade show exhibits, and as an intermediate solution before low-volume manufacturing.

Prototypes frequently reveal opportunities for redesign, enhancement, and adjustments that may not be apparent from digital models alone. As such, they serve as valuable tools for refining a design before significant resources are allocated to mass production. Identifying and resolving design flaws early in the development process can ultimately save far more than the initial cost of prototyping, making it a strategically sound investment.

Selecting the Optimal Rapid Prototyping Technique

Choosing the most suitable rapid prototyping method depends on balancing several key factors: your budget, the complexity of the part, the intended purpose of the prototype, and your project timeline. Higher-fidelity prototypes typically require a greater investment of time and money, but they also provide a more accurate representation of the final part’s form, fit, and functional performance.

To identify the best approach, consider asking yourself the following:

Will the prototype serve as a static visual model?

Is full functionality required?

Does the design include multiple moving or assembled components?

What level of surface finish and texture is needed?

What material does the prototype need to be made from?

How important are mechanical properties such as strength and durability?

How closely must it resemble the end-production part?

These are just a few of the important questions to weigh—every project comes with unique requirements. While we can’t address every variable here, reflecting on these aspects will help guide your decision.

23+ Years of Excellence in Injection Molding & Tooling

For over two decades, Livepoint has been a trusted partner for global brands and innovative startups in need of high-precision injection molding and mold manufacturing. Our legacy of excellence, built since 2003, is rooted in technical expertise, relentless quality, and an unwavering commitment to customer success.

Here’s why industry leaders continue to choose us:

🔹 Proven Experience & Stability

With 23 years of specialized experience, we’ve mastered the art and science of injection molding. Our long-standing presence reflects reliability, continuous improvement, and deep industry knowledge.

🔹 End-to-End Solutions

From DFM assistance and rapid tooling to full production runs, we offer integrated services that simplify your supply chain and accelerate time-to-market.

🔹 Precision Tooling Built to Last

We build molds that perform—durable, high-precision, and optimized for efficiency. Our tooling capabilities include multi-cavity, family molds, and hot runner systems, all manufactured in-house using advanced CNC, EDM, and grinding technologies.

🔹 Quality That Meets Global Standards

Our rigorous quality management system and full-dimension CMM inspection ensure that every part—from prototype to mass production—meets international standards and your exact specifications.

🔹 Customer-Centric Partnership

We don’t just supply parts; we build relationships. Our team provides responsive communication, transparent project management, and engineering support tailored to your goals.

🔹 Sustainable & Scalable Manufacturing

Whether you need 50 prototypes or 500,000 production parts, we deliver scalable solutions with consistent quality, on time and within budget.

Trusted Since 2003. Built for Your Next Project.

Reach out today to experience the difference that 23+ years of expertise can make.

Precision components with IATF 16949 compliance

Molding and parts

CE/ROSH certified high-gloss finishes

Wear-resistant engineering plastics

| Direct Rapid Tooling | Indirect Rapid Tooling | |

|---|---|---|

| Pros |

|

|

| Cons |

|

|

Rapid tooling refers to a specialized manufacturing service that produces specific types of plastic injection molds and final parts in significantly less time compared to full-scale production tooling. This approach emphasizes optimized design, streamlined fabrication, and strategic material selection to maximize production efficiency and reduce downtime.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

As a leading global molding manufacturer with 20 years of industryexperience, we have the expertise to provide custom injection molding services tailored to your product needs. We offer various surface finish options for plastic parts, ensuring the final product meets your exact specifications. If you have any additional surface finish requirements, please feel free to contact us.

As a leading global molding manufacturer with 20 years of industryexperience, we have the expertise to provide custom injection molding services tailored to your product needs. We offer various surface finish options for plastic parts, ensuring the final product meets your exact specifications. If you have any additional surface finish requirements, please feel free to contact us.

| Direct Rapid Tooling | Indirect Rapid Tooling | |

|---|---|---|

| Pros |

|

|

| Cons |

|

|

As a leading global molding manufacturer with 23+ years of industryexperience, we have the expertise to provide custom injection molding services tailored to your product needs. We offer various surface finish options for plastic parts, ensuring the final product meets your exact specifications. If you have any additional surface finish requirements, please feel free to contact us.

Engage in in-depth communication with the customer to understand their requirements, including work scenarios, types of tasks, performance requirements etc.

Design a specialized robot solution that meets their needs, including robot structure, control system, sensor configuration etc.

Produce prototypes according to the design, conduct testing, and optimization.

After testing and optimization, proceed with mass production to ensure product quality and delivery timelines.